Fiber structures and fiber types

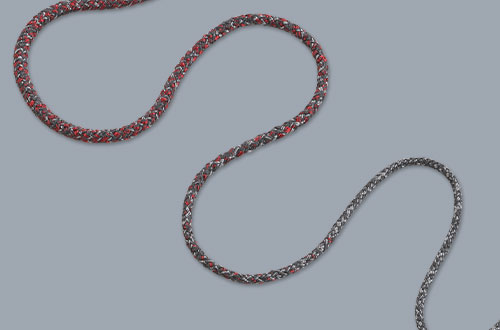

Overview of fiber structures

Monofilaments

A few comparatively thick fibers (Ø 0.3 mm) are fed in parallel to the braiding process.

Multifilaments

Many very thin fibers (0.001 mm) are used as a bundle during the braiding process. This is the most widely used type of construction in yachting ropes.

Textured fibers

The fibers are not arranged in parallel in the bundle but exhibit a more or less random type of arrangement. This is why the fiber bundle has a comparatively rough surface.

Overview of fiber types

Ultra High Modulus Weight Polyethylene (UHMWPE) = Robtec, Dyneema®, Spectra, etc.

UHMWPE producers change polyethylene on a molecular basis and turn the fibers in one direction. The result is UHMWPE; a material that exhibits increased breaking loads (very low elongation at break for synthetic fibers) and reduced stretch. Furthermore, UHMWPE has a very low specific weight that imparts buoyancy, good abrasion strength, and resistance to sunlight. The only downside of UHMWPE is that it creeps. This means that the fiber will show permanent elongation under load. However, due to its impressive advantages, UHMWPE is the most widely used high-tech fiber in the yachting rope segment and is particularly well suited for use as a core material for high-tech cordage. The core bears the load, while the cover merely serves as protection against abrasion and light. Therefore, it is possible to remove the cover from the rope ends without reducing the rope's breaking strength. This is why UHMWPE can be used for all high-quality products such as sheets, halyards, and trim lines. Due to the slippery surface and the “self-lubrication” of UHMWPE fibers, they are ideal for all applications where a reduction of chafe and friction is needed.

Polybenzoxazole crystal polymer (PBO)

The Japan-based Toyobo Corporation produces Polybenzoxazole Crystal Polymer (PBO). PBO is a high-tech fiber that combines very high breaking loads with minimal stretch and high-temperature resistance. Its only weakness, however, is its extremely low resistance to sunlight. The fiber offers high abrasion resistance and a very smooth operation on winch drums. This characteristic makes PBO the number one choice if you want to operate extremely high-loaded ropes without noisy winch operation.

Aramid = Kevlar®, Twaron® or Technora®

Japan-based Teijin produces Twaron® and Technora® fibers, while U.S.-based DuPont produces Kevlar®. Each of these products is a para-aramid fiber made of co-polymers. In the yachting ropes segment, this fiber is highly appreciated mainly because it exhibits zero stretch, high breaking loads, and extremely high-temperature resistance. This makes it ideal for use as a cover fiber for winches. However, it is sensitive to sunlight.

Polyester (PET or PES)

Polyester offers a great number of chemical and physical advantages. It boasts relatively good breaking loads and low stretch as well as salt-water resistance, good abrasion resistance in both dry and wet conditions, and good resistance to sunlight. In view of this large number of benefits, PES is used frequently for the production of yachting ropes. In the cruising segment, it serves as material for both cores and covers of halyards, sheets, and mooring lines. Due to the high density of this material and the fact that it sinks after time it finds its application as an anchor line. In medium-tech applications, it is often used as a cover material in order to protect core materials that are sensitive to UV light.

Polyamide (PA)

Apart from a high breaking load and stretch, Polyamide is very abrasion resistant, a fact that is even better in wet than in dry conditions. This fiber absorbs up to 7% water, which makes it applicable as material for mooring or anchor lines. However, when kept in contact with moisture for too long, Polyamide can become stiff. Another downside compared to Polyester is its lower UV resistance.

Polypropylene (PP) = XLF

PP is extremely lightweight and even buoyant. It exhibits sufficient abrasion and temperature resistance. PP is used for simple applications in the yachting rope segment. Its relatively high stretchability makes Polypropylene a popular material for allround ropes, towing lines, and simple mooring lines.