ROBLINE X SUSTAINABILITY

Robline lives for water sports! However, we recognize that our activities have an effect on both the local and global environment.

Talking about local environment, Austria, where the headquarters of Robline is located, is one of the leading countries in Europe in the field of environmental policy. In 2016 the an average Austrian only generated around 42 kg waste per capita in comparison to Italy with 65kg plastic waste per capita. Around a third (28%) of this waste (around 0,92 Mio tons) is re-used, the rest is burnt under high temperature so that no toxics can leak. Besides this, with an average annual precipitation of around 1,100 mm Austria is one of Europe’s most water-wealthy countries. And about 50% of the drinking water used in Austria is from groundwater resources, 50% from springs. Water is also used for generating energy in this country.

Looking on a more global perspective, this is not enough for Robline. By transitioning into a more holistic approach towards sustainability, we try to adapt our processes and reduce the company’s carbon footprint gradually - with recycling, reduction of petroleum-based materials, and an optimized use of these materials.

The Fiber Ropes department at Teufelberger has set itself the following goals by 2030:

- To minimize the use of resources by offering opportunities to recycle ropes and by granulating plastic spools in-house.

- To offer climate-neutral products and focus on sustainable packaging solutions.

- To inspire and educate sportsmen and women to protect the limited resources of our oceans and lakes.

By implementing and revisiting these goals annually, Robline still focuses on the performance of its products and tries to balance the requirements of its customers by improving all processes.

FIRST. Innovation with recycled PET – RIO GREEN & SIRIUS GREEN

Inspired by the strict environmental policy in Austria, Robline started to rethink its dockline “Rio”, and introduced a sustainable version, the “Rio Green”. Our eco-conscious Rio Green is made from 100% recycled waste plastic bottles while not giving in any of its well-known characteristics of durability, longlivity and price-performance ratio in the dockline business.

Learn more about the product here ...

| Ø (mm) | Length (m) | MBL (daN) | Weight (g/m) | Color/Item Nr |

| 10 | 200 | 1800 | 69 | 7155464 |

| 12 | 150 | 2500 | 97 | 7155465 |

| 14 | 100 | 3500 | 127 | 7155466 |

| 16 | 150 | 4000 | 163 | 7155463 |

With the same sentiment when introducing Rio Green - to make water sports more sustainable - Robline now also offers a more environmentally conscious version of one of our most important products for Cruising. Sirius Green follows the same concept as our Sirius 500 – low stretch, high stability, but 100% recycled polyester. Its construction has been adopted to the needs of the recycled polyester fiber.

Learn more about the product here ...

| Color/Item Nr | |||||||

| Ø (mm) | Length (m) | MBL (daN) | Weight (g/m) | grey-blue | grey-orange | grey-yellow | grey-white |

| 8 | 200 | 1800 | 56 | 7155945 | 7155943 | 7155942 | 7155946 |

| 10 | 200 | 2800 | 71 | 7155947 | 7155950 | 7155952 | 7155948 |

| 12 | 150 | 3800 | 103 | 7155953 | 7155956 | 7155958 | 7155954 |

Cover: rPET, Core: rPET

SECOND. No plastic in our packaging

The new packaging of all our Ready-Made products is a result of great teamwork across borders at Robline. New ideas often root in the heads of attentive colleagues and are part of our sustainability strategy. Until now, Ready-Made Yachting Ropes, such as the Ready-Made Rapallo, or Soft Shackles, have been delivered to customers in plastic packaging - that is, in a plastic bag with a cardboard label. Considering that over 200.000 pieces sold in 2020, this also means that the same amount of plastic bags and cardboard headers left our factories with these products. Three teams over four countries worked on the new packaging.

In the future, these products will come with a plain cardboard strapping and a polyester cord for hanging in the store. In addition to reducing plastic waste, the delivery weight is smaller, which makes a big difference from a logistics perspective. Furthermore, European manufacturers supply the strapping, which reduces additional CO2 consumption when they deliver raw materials to our plants. For the end consumer, this means less unnecessary plastic waste on their boats, which is conducive to our - the protection of our oceans and lakes. The switch to paper strapping thus makes the products more application-oriented as the cardboard is easily recycled in cardboard paper waste.

THIRD. Minimizing waste by reusing and recycling plastic material in-house

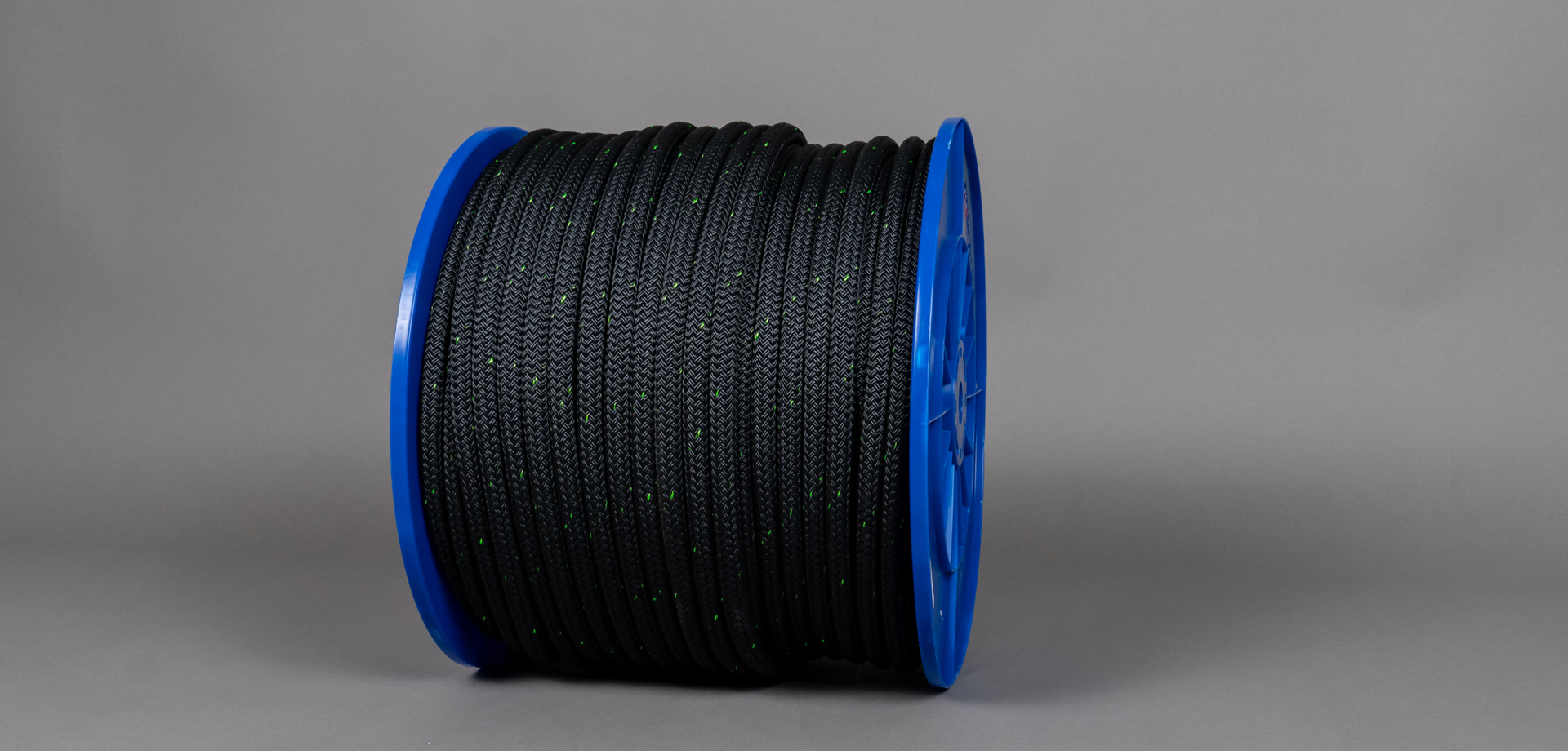

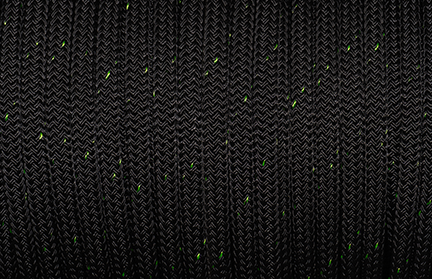

Plastic is the main component of Robline products. This is due to the unique properties of the material and its versatile applications. However, against many people's knowledge, pure plastic is very recyclable - Robline has taken this to heart and therefore uses spools made of pure polypropylene. In contrast to other rope manufacturers, it is important for us to avoid composite materials like carton, metals, plastics, or wood as all of them complicate the recycling process. Even cardboard spools have a negative impact on nature due to the high effort of gluing and stabilization by varnish. Thus, all Robline products are delivered to customers in various lengths on plastic reels made of polypropylene. The goal in switching to rolls made of polypropylene is to retrieve the empty spools from our customers and reuse them.

With our in-house regranulation machine, used PP rolls can be returned to the raw material cycle for our strapping products. The highlight: pure plastic material can be recycled in its entirety, provided the necessary technology is available. Current framework contracts with our customers are still being processed with the previous rolls, by which time the plant will have switched over to the new rolls made of pure polypropylene. From then on, none of our customers will have to worry about recycling themselves. We will take back our own waste, manufacture new products in our plants by means of a regranulation process, and thus set an example in the industry - for our future!